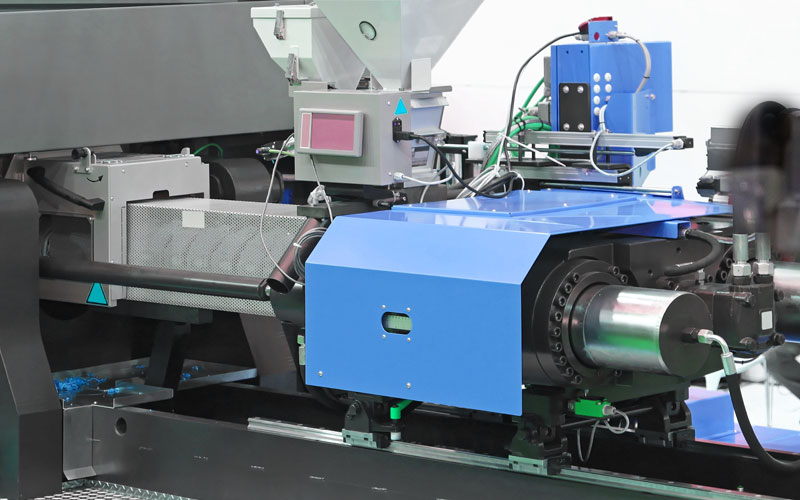

HES Series: Hybrid energy saving for injection molding machines

Delta's Hybrid Energy Saving (HES) System provides precise pressure and flow controls for injection molding processes. It also reduces losses from waste energy, which are a major disadvantage of the traditional injection molding machine. This solution helps to improve product quality, market competitiveness and productivity.

Specifications

- Superior Energy-Saving Outcomes: Lower energy consumption rate at the clamping and cooling stage while providing high productivity and high precision. 40% less energy consumption compared to a variable pump hydraulic systems. 60% less energy consumption compared to a traditional quantitative pump hydraulic system.

- Low Oil Temperature: Oil temperature reduced by 5~10 oC; oil usage reduced by 50~60%; requires 50% less oil tank volume; lower cooler specifications required and for some cases cooler is not required.

- High Duplication Accuracy: Precise flow and pressure control featuring duplication of products with less than 0.09% difference.

- Long Holding pressure: Keeps mold halves securely closed for a longer period for thick plastic products formation.

- Good Frequency Response: When uses Delta HES with permanent magnetic servo motor (PMSM) speeds up frequency response to 50ms.

- Suitable for Harsh Environments: The resolver used in Delta HES is resistant to earthquakes, oil and dust.

- Old Machine Replenishment: Supports analog command 0~10V and linear correction (3 points), no replacing.

- Flow Convergence: Saves cost on tubes, large flow capacity, enhances energy-saving.

DEN_IA_VFD_87_Hz_Technique_TN_EN_20220621.pdf

PDF, 656.63 KB Technical Note - 87 Hz Technique 26.11.2021

PDF, 656.63 KB Technical Note - 87 Hz Technique 26.11.2021

DELTA_IA-MDS_HES-C_C_EN_20210611_Web.pdf

PDF, 2.28 MB Delta Hybrid Energy Saving System HES-C Series Catalogue 11.06.2021

PDF, 2.28 MB Delta Hybrid Energy Saving System HES-C Series Catalogue 11.06.2021

DELTA_IA-MDS_VFD-HES-ECMA_A_CE_20081022.pdf

PDF, 18.69 KB EC Declaration of Conformity AC Servo Motor ECMA Series 22.10.2008

PDF, 18.69 KB EC Declaration of Conformity AC Servo Motor ECMA Series 22.10.2008

DELTA_IA-MDS_EMC_I_EN_20110208 .pdf

PDF, 468.78 KB AC Motor Drives EMC Standard Installation Guide EMC Compliance Practice 08.02.2011

PDF, 468.78 KB AC Motor Drives EMC Standard Installation Guide EMC Compliance Practice 08.02.2011

DELTA_IA-MDS_VFD-ALL_RoHS_20200227.pdf

PDF, 708.99 KB RoHS Declaration of Conforimty 27.02.2020

PDF, 708.99 KB RoHS Declaration of Conforimty 27.02.2020

DELTA_IA-MDS_VFD-HES_UM_EN_20190222.pdf

PDF, 9.37 MB Delta Hybrid Energy Saving System HES Series User Manual 22.02.2019

PDF, 9.37 MB Delta Hybrid Energy Saving System HES Series User Manual 22.02.2019

DELTA_IA-MDS_VFD-ALL_RoHS_20190807.pdf

PDF, 360.21 KB RoHs Declaration of Compliancy 07.08.2019

PDF, 360.21 KB RoHs Declaration of Compliancy 07.08.2019

DELTA_IA-MDS_VFD-HES-ECMA_UL_20121014.pdf

PDF, 98.03 KB UL Certification - Servo and Stepper Motors 14.10.2012

PDF, 98.03 KB UL Certification - Servo and Stepper Motors 14.10.2012

Injection Molding Machine

Injection Molding Machine